MENU

My First Completed Robot Arm Rotate and pan around the 3D model for this project below!

Rotate and pan around the 3D model for this project below!

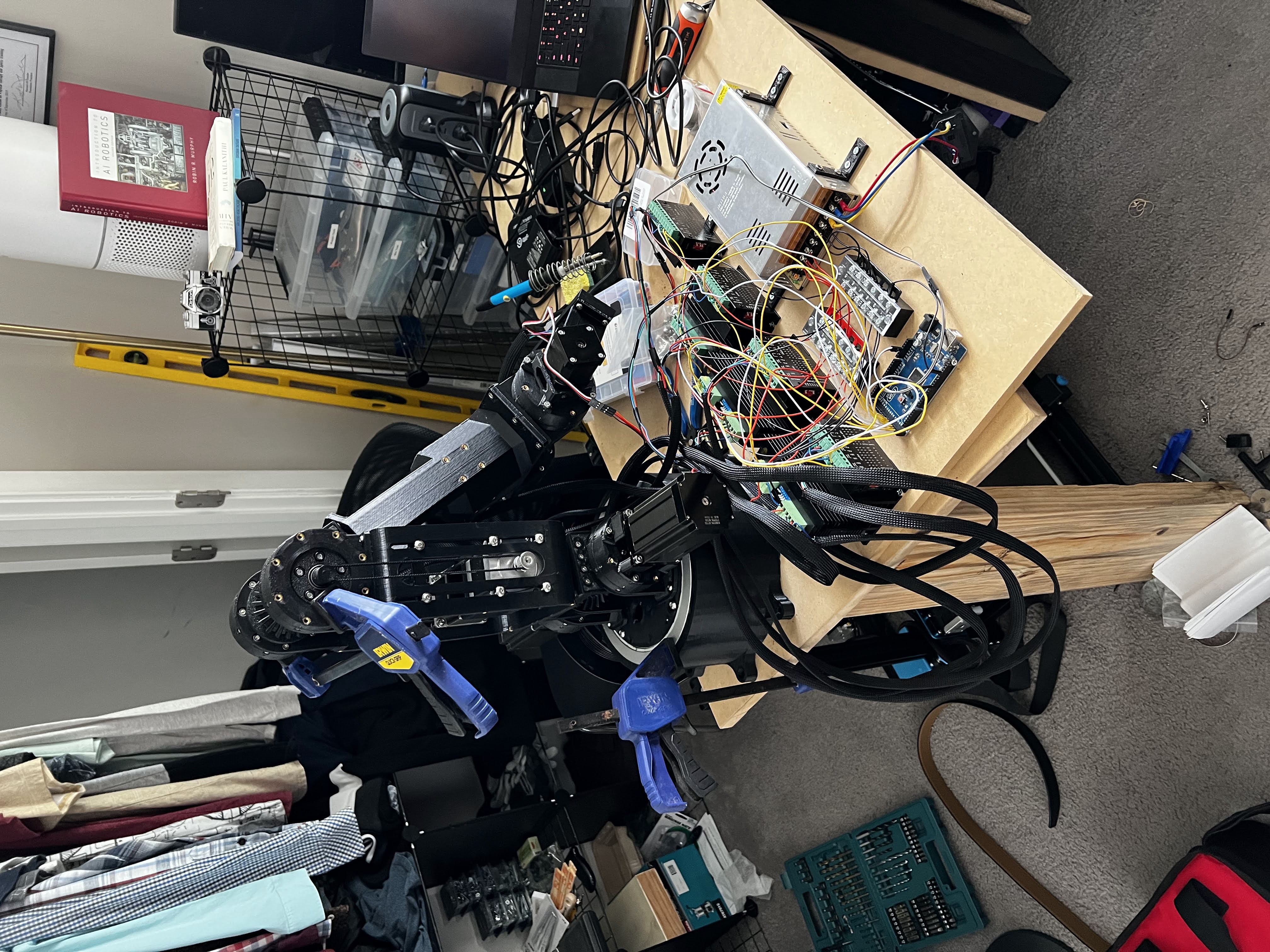

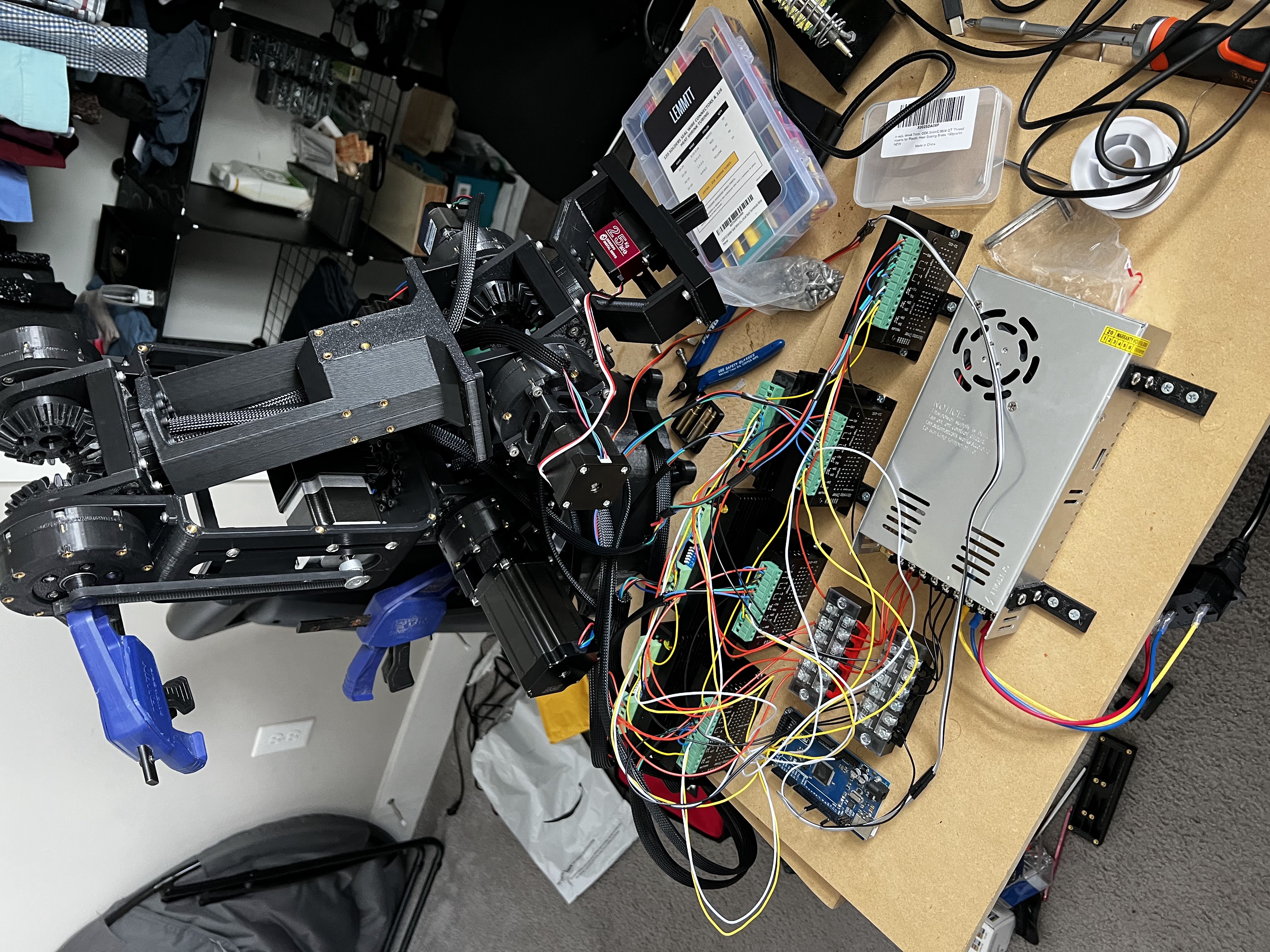

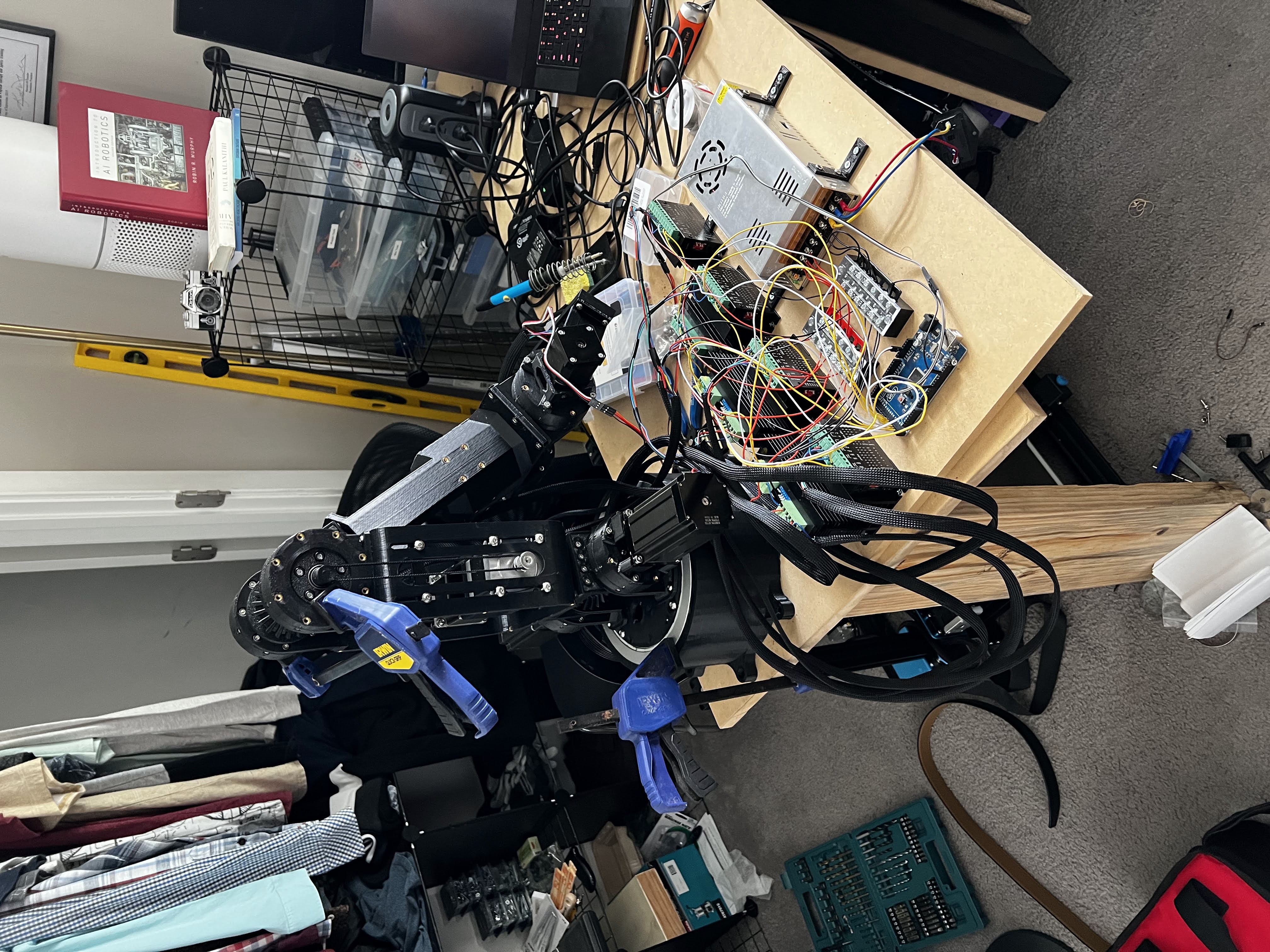

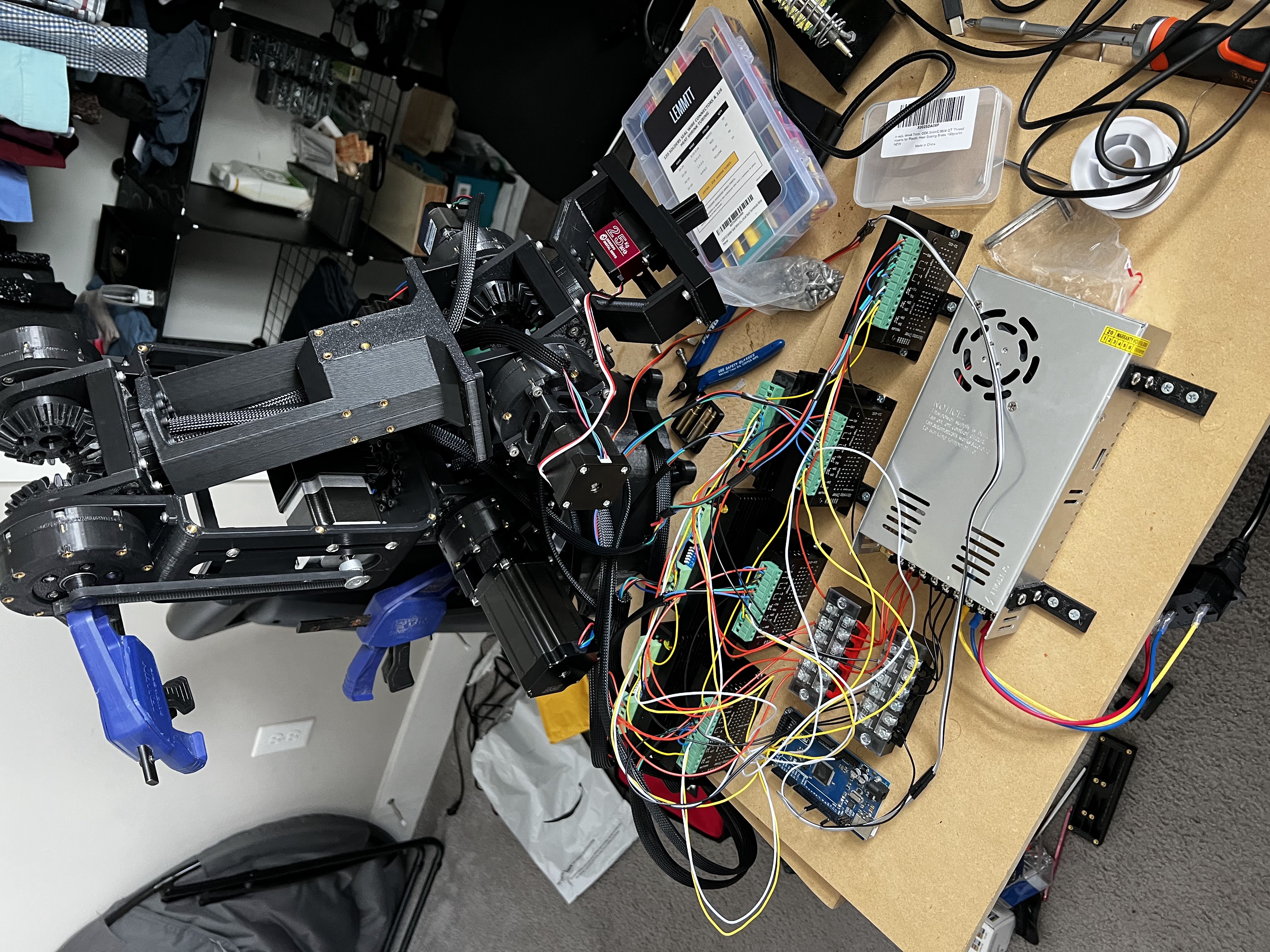

This is the first completed version of my 3D printed 7-axis robot arm. The design specs of this project were to create an inexpensive 7-axis robot arm that has a reach of at least 750mm and a payload capacity of at least 2 kg at full extension.The way I went about meeting these specifications is by first calculating the torque necessary at each of the joints to lift up 2 kg at full extension. I then selected the respective size of stepper motors (since stepper motors are cheap) and then designed a 20:1 3D printed cycloidal gearbox that would work with all of my motors to multiply their torque by quite a bit. For each of the joints besides the base, I also combined the torque of two motors by using a differential system. I also made each of the joints hollow shafted so that cable management would be easier in the end. I also made a servo based parallel end effector to grab small objects easily for initial testing.There are many changes that I would implement in the next versions of the robot arm, such as IMU based backlash compensation and gravity compensation, a fully featured ROS interface, as well as smarter 3D printing and material choices for the shoulder joints since they bear the most load and are the most failure prone currently. However, I am quite happy with my progress so far!Below are some demos of the robot arm, along with some photos of the arm at various angles.

Short Demo of Robot ArmLonger Demo of Robot arm